Over 100 years of experience.

Undercarriages literally “move” equipment. And Berco has been the world’s leading OEM manufacturer of undercarriage systems and components for the biggest names in heavy equipment for more than 100 years. So, chances are, a Berco undercarriage is already moving your machine.

Back in the days Berco opened up in Italy as a little repair shop. Capitalizing on his extraordinary vision and mechanical ability, Vezio Bertoni transformed the shop into a workshop and then a factory. The company continued to develop further, extending its range to different kinds of machine tools (especially grinders), and continued to expand over the following years.

It was only during the 1930s that the Ferrara-based company entered the undercarriage market, soon becoming one of the most important players among the undercarriage manufacturers in the world. During the late 1970s, the Bertoni family started the process that would transfer ownership to the Hoesch Group, then to Krupp and finally, at the end of the 1990s due to the merger of Thyssen and Krupp, to thyssenkrupp.

In 1918 Vezio Bertoni opened up a bicycle repair shop, continuing his father’s work

Soon he also began to repair agricultural machinery and vehicles abandoned by the US Army in the countryside of Ferrara. Vezio Bertoni relied on his competence and his fellow citizens, so shortly the small shop turned into a workshop of 30 employees and began to produce also machine tools and spare parts for tractors.

Roberto Cotti

joined Vezio Bertoni

When the entrepreneur Roberto Cotti joined Vezio Bertoni, the company became the “Bertoni & Cotti”. The production was extended to different machine tools: grinding machines, boring machines, presses, lathes, sanding machines, and equipment for workshops.

5000 square meters of covered area

The company was by far the largest and most important industry in the region (5000 square meters of covered area) with over 100 employees. Berco products started to be exported to other European countries.

There were

824 employees

There were 824 employees and the company was getting bigger and bigger, but the outbreak of the World War II compromised the growth. After 2 years of almost total inactivity, Berco got back on its feet in 1946 and renewed itself, starting to produce components for tracked machines, overhaul equipment for earthmoving machines and presses for assembly chains.

The factory has doubled its size and has been renovated and modernized

In 1957, the business partner Cotti resigned and Gianni Bertoni, son of Vezio, replaced him. The factory doubled its size and was renovated and modernized.

Berco was one of the most important companies in its sector not only in Italy

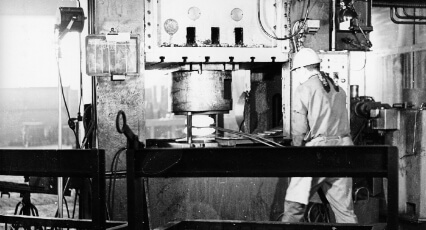

Berco was one of the most important companies in its sector not only in Italy but also in foreign markets all over the world: 60% of the undercarriages produced were exported to the US and Canadian markets and Berco authorized dealers were about 120. The first hot-forging workshop in the region was built with an area of 3000 square meters and 27 of the most powerful and modern machines on the market Berco called its own.

Gianni Bertoni officially became CEO of the company

Gianni Bertoni officially became CEO of the company, launching it to globalization. In 1976 he sold 50% of the company to the German steel multinational Hoesch.

Berco

International

Berco covered 35% of the entire national undercarriage production and 6 out of 10 spare parts exported overseas were produced by the company, 50% of which were shipped to the US. At that time the US market was in a crisis and in order to save the company Bertoni sold the remaining 50% to Hoesch. Under the 100% Hoesch ownership, Giovanni Bertoni, Gianni’s son, became CEO and he led the entry into the OEM market, restructuring plans, new investments and technological innovation.

Important

Customers

Berco boasted important customers like Komatsu, John Deere, Liebherr and Volvo as well as important representatives of the Middle Eastern market such as United Motors and Middle East. In 1992 the German multinational Krupp acquired the Hoesch group, giving life to the Krupp AG company Hoesch-Krupp. In 1998, Krupp AG merged with Thyssen AG, giving birth to ThyssenKrupp.

The share of exported products reached 90%

The share of exported products reached 90% and Berco reached the goal of 230,000 tons of finished product in a fiscal year. Berco continued to grow, with now over 3000 employees and three foreign branches: Berco of America in Waukesha, (WI), Berco South America in Campo Limpo (SP) and Berco Bulgaria in Apriltsi.

The new BU, Forged Technologies, was created

Berco automated many of its production lines and the OE business continued to be its most important segment. In October 2017 two Business Units of the thyssenkrupp AG, Undercarriages, Forging and Machining were merged to the new BU Forged Technologies.

Berco Aftermarket S.r.l. The New Company

In October 2022 Berco announced the launch of ‘Berco Aftermarket S.r.l.’ The new company will be dedicated exclusively to serving the Aftermarket and is 100 percent owned by Berco S.p.A. As a spin-off of the existing business, Berco Aftermarket S.r.l. will focus on providing a high-quality and ultra-efficient replacement parts service. Berco UC solutions are based on the markets, customers and technical data, and now the company is able to provide engineering capabilities and technical support anywhere in the world.