Supply range

- Berco creates track chains with reinforced links and shoes, stronger pins and bushings for heavy-duty, high impact applications and highly abrasive soil.

- BPR2TM version (Berco Positive Pin Retention 2TM) for high-impact applications improves the working lifetime of components by mechanically locking the pin to the link, which results in the avoidance of ‘end-play generation’ and ‘pin walking’ in a track chain.

- All weather version for temperatures ranging from -45°C to 50°C.

Mining

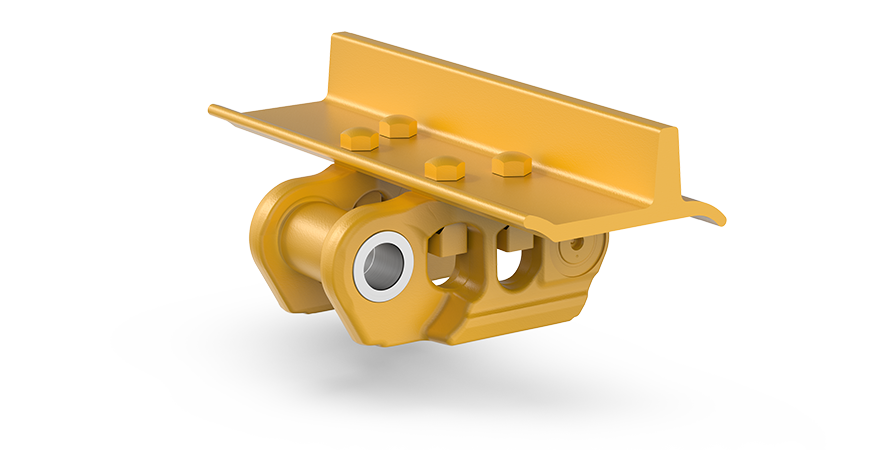

Mining Dozer track chains

Track group assembly for mining bulldozers

Chain features

- Chain pitch ranging from 240-318 mm.

- Newly developed sealing system and Berco positive pin retention (BPR2) provide maximized joint durability.

- Berco design extends track chain life and allows to plan predictive maintenance with reusability of the inner components.

Shoe features

- Single grouser common for dozers.

- High-grip track shoes are required to facilitate dirt removal.

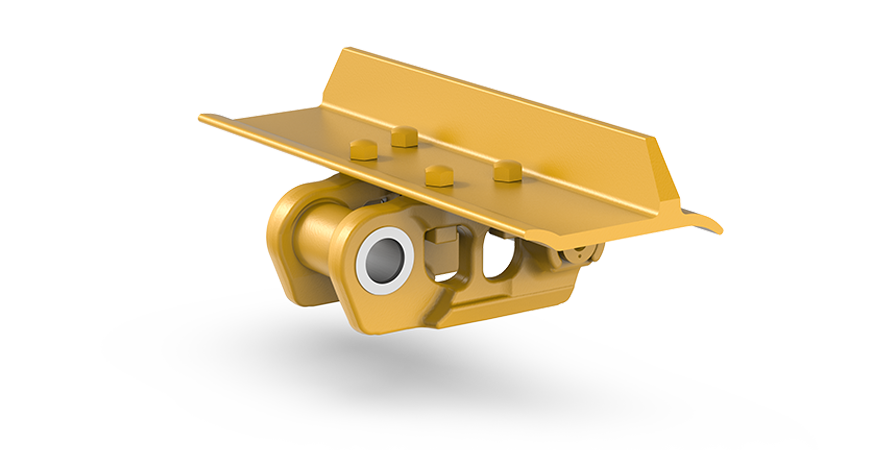

Mining Excavator track chains

Track group assembly for mining excavators

Chain Features

- Chain pitch ranging from 318 | 350 | 395 mm.

- Conventional chain design with forged track link and forged shoe plate.

- Each component is designed with optimized steel grade and heat treatment to accomplish the “mission”.

Construction

Construction Dozer track chains

Track group assembly for medium size bulldozers

Chain Features

- Stepped bushing available on selected machine models.

- The track chain reduces friction between components and fuel consumption.

Link Features

- Taller track link profile for more wear material.

- Deeper heat treatment case depth.

Shoes Features

- High grip track shoes required to facilitate dirt removal.

- Clipped corner and mud hole as options.

Construction Excavator track chains

Track group assembly for medium size excavators

Chain Features

- Track link with optimized design in the main structural sections.

- Pin and bushing with selected material and heat treatment for high load and high impact resistance.

Press-fit type master pin

- Used in more severe applications, it requires a field press for the assembling procedure.

T-type master pin

- Low severity application and service, which doesn’t require a field press for the assembling procedure.