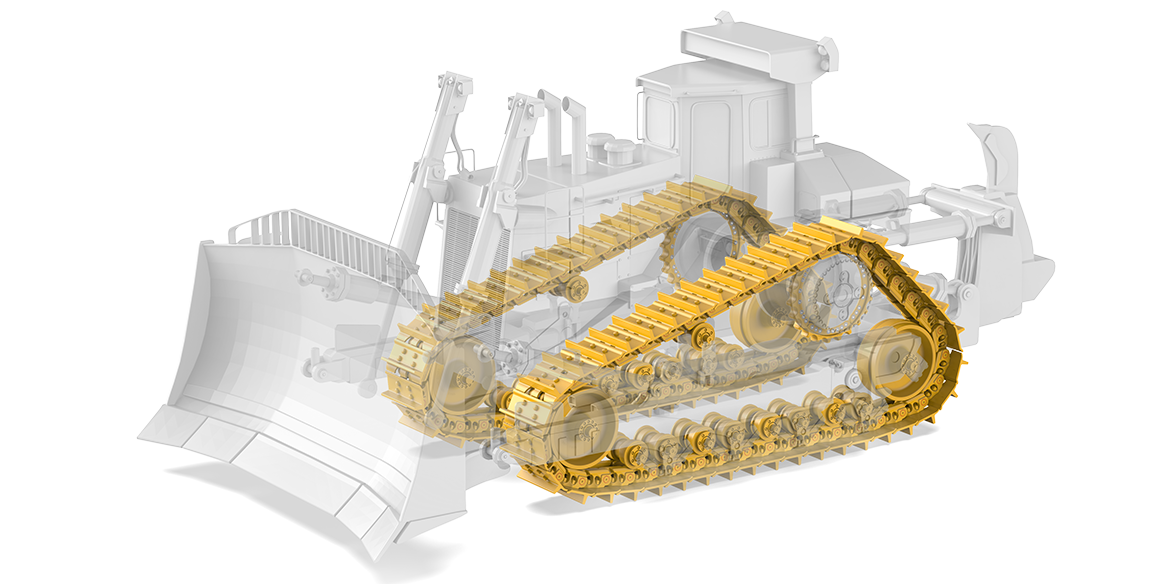

New CAT® D11 Undercarriage

Performance depends from several factors: at Berco we do our best to provide the best to our customers.

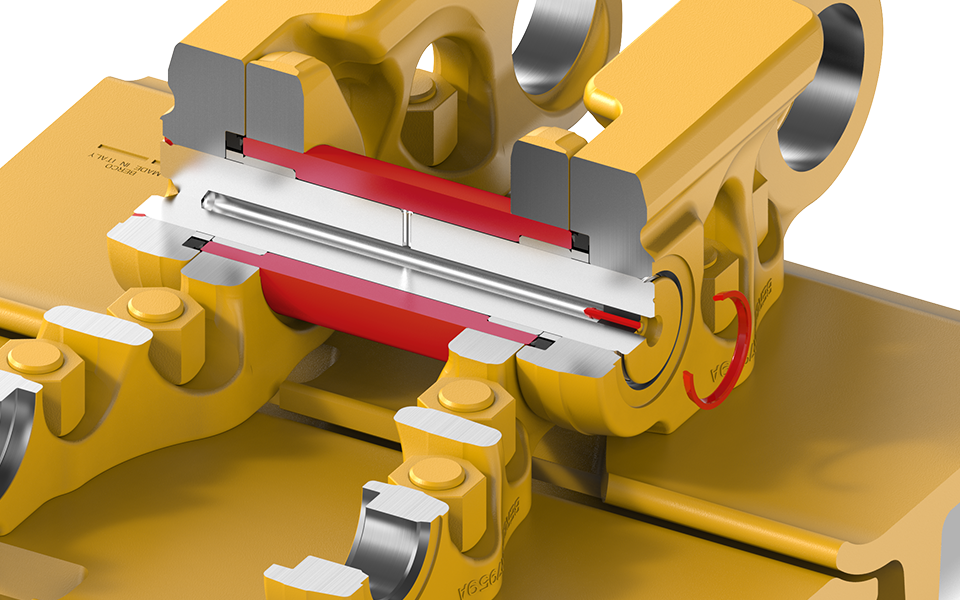

Optimised design, quality of materials and precise control of each stage of the production process all contribute to improving the life of the undercarriage and reducing the total cost per hour. Berco provides the complete machine for CAT® D11 application: track rollers, carrier rollers, segments, idlers, shoes and a complete renewed track chain. The track chain boasts a new design that guarantees to maximize the productivity of your operation taking care most deeply of lubrication of internal parts.

Technology & Innovation

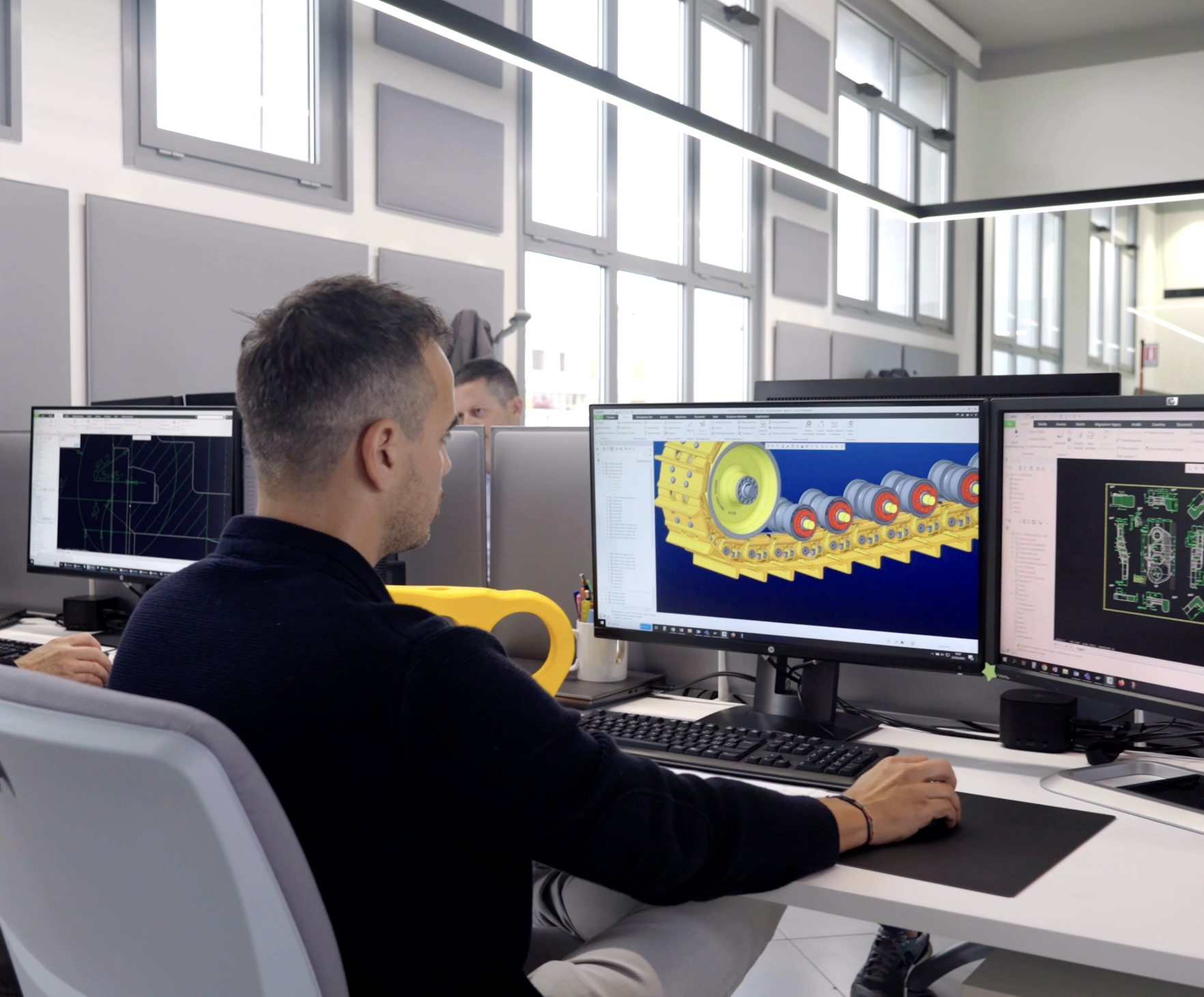

For Berco, innovation means introducing efficient and innovative technology capable of extending average undercarriage component life, thus reducing our customers’ operating costs.

Our R&D involves close collaboration with customers, as well as with our technicians from the Technical, Quality, Product Support and Production Engineering teams. Assisted design tools and other technical instruments are used during engineering and prototyping to design, test and optimize each part before production. Our metallurgical laboratory has specific skills and sophisticated instruments to validate products in all fields of use.

Reliability tests are carried out on undercarriage components to compare durability and performance across various fields of application. Viewing techniques and artificial intelligence are used to automatically inspect each part to significantly reduce faults.

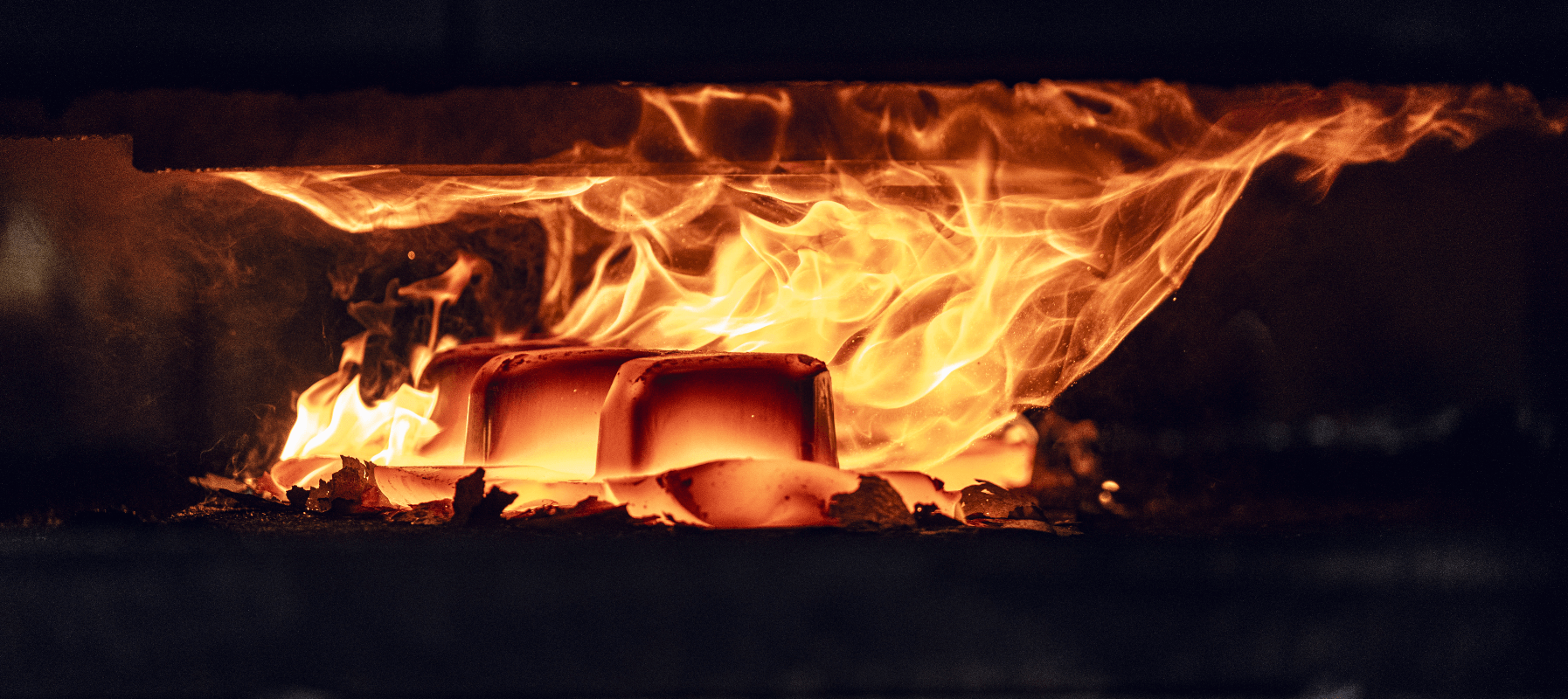

With this approach, we can develop new materials and fine-tune heat treatment processes to guarantee superior, durable products.

Technical improvements

Improved design and enhanced internal lubrication, greater stability and weight distribution. The best solution for high abrasive mining applications.

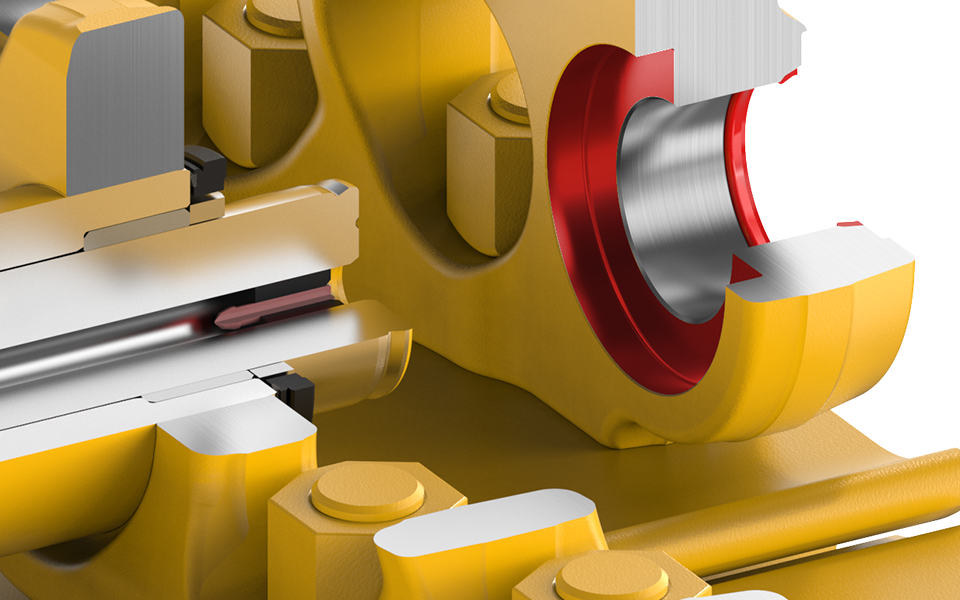

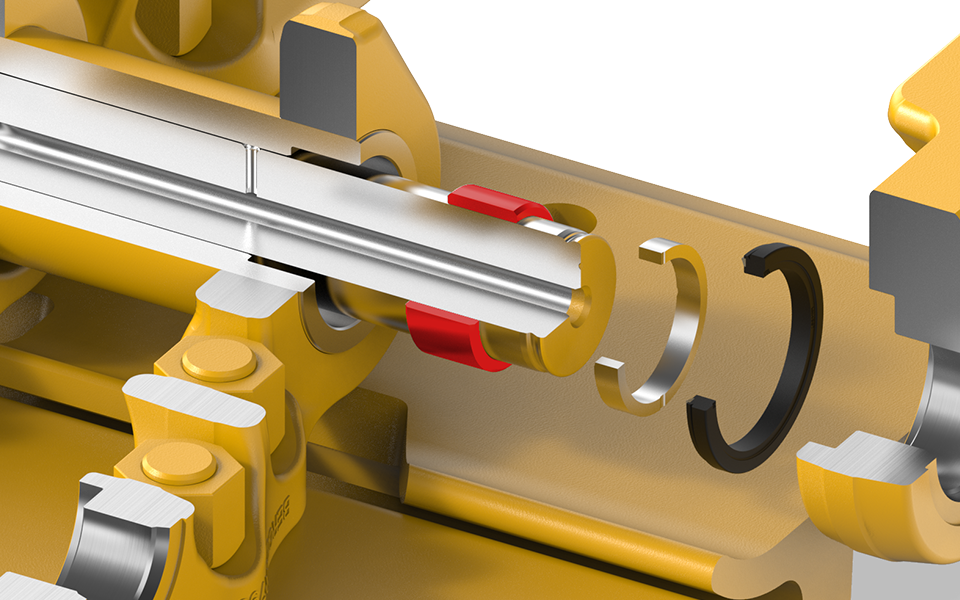

Bushing QT

Material selection and heat treatments to maximize wear resistance.

Bushing is bringing other innovation points compared to standard product. The new shape required the selection of specific material combined with a unique heat treatment.

Sleeve Bearing

Accurate machining is ensuring the best fit condition to sleeve bearings thus significantly reducing the galling on the track pins.

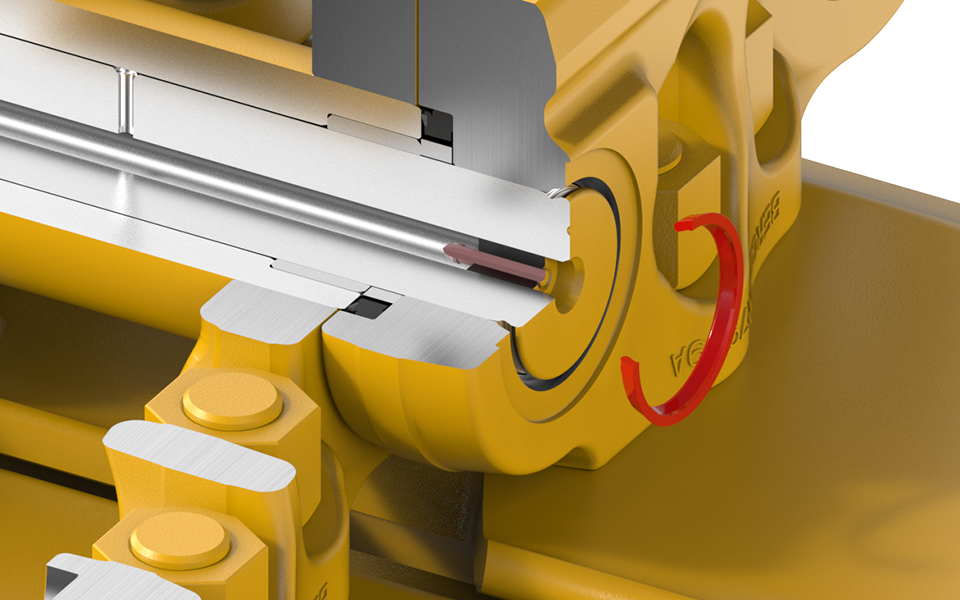

BPR2 TM

Stronger joint stability

BPR2TM and Sleeve bearing design will allow to a have a regular planned maintenance and maximize the re-usage of the components.

Seal Labyrinth

New design had as main focus to enhance the seal protection: for this purpose a new seal has been re-designed and labyrinth around the seal lip itself has been also re-defined by extending the bushing length.